In the Realm of Accuracy: Precision Manufacturing Insights

Precision manufacturing is a cornerstone of modern industry, where accuracy and attention to detail are paramount. In this blog post, we will delve into the realm of precision manufacturing and explore its significance in creating high-quality products.

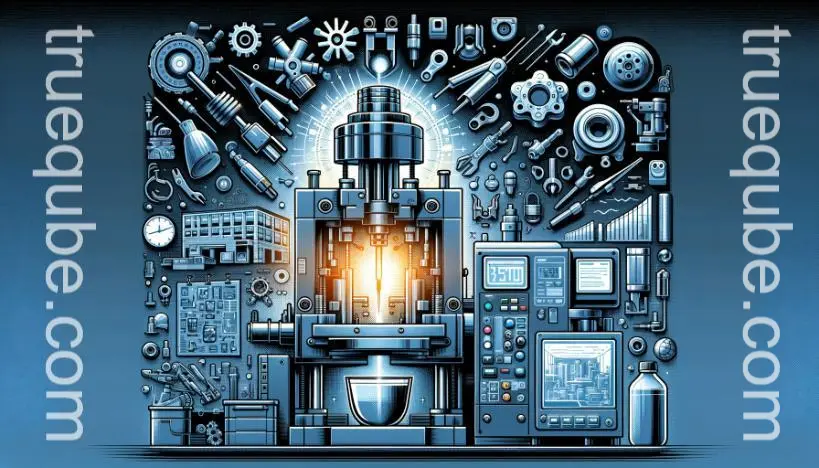

One of the key tools in precision manufacturing is the injection molder. An injection molder is a machine used for the manufacturing process to produce parts in large volumes. It is most commonly used in producing complex, high-precision parts with excellent finish quality.

The injection molding process involves injecting molten material into a mold, which is then cooled and solidified into the final part. This method allows manufacturers to achieve high levels of accuracy and consistency, making it invaluable in the realm of precision manufacturing.

Discover the technologies, techniques, and best practices that contribute to precision manufacturing and ensure exceptional accuracy in every step of the production process.

1. The Importance of Accuracy in Manufacturing

In the world of manufacturing, accuracy is critical to producing high-quality products. Even slight variations or deviations can have significant impacts on functionality, reliability, and overall performance. Precision manufacturing focuses on achieving the utmost accuracy in every aspect, from design and prototyping to production and assembly.

2. Advanced Technologies for Precision Manufacturing

Precision manufacturing relies heavily on advanced technologies that enable precise measurements, cutting-edge machining, and quality control. Computer Numerical Control (CNC) machines, laser cutting, 3D printing, and robotic automation are just a few examples of technologies that contribute to precise and accurate manufacturing processes.

3. Design for Manufacturability

Design for Manufacturability (DFM) is an essential principle in precision manufacturing. It involves designing products with manufacturing processes in mind, considering factors such as material selection, tolerances, and assembly methods. By optimizing designs for manufacturability, manufacturers can streamline production and improve accuracy.

4. Quality Control and Inspection

Implementing rigorous quality control measures is crucial in precision manufacturing. Regular inspections and testing throughout the production process help identify any deviations or defects, ensuring that only products that meet strict accuracy standards are released. This commitment to quality control guarantees consistency and customer satisfaction.

5. Statistical Process Control

Statistical Process Control (SPC) is a methodology used in precision manufacturing to monitor and control production processes. By collecting and analyzing data, manufacturers can identify trends, detect variations, and make informed decisions to maintain accuracy and improve overall quality. SPC enables continuous improvement and drives precision in manufacturing.

6. Training and Skilled Workforce

Precision manufacturing requires a highly skilled and trained workforce. It involves operating sophisticated machinery, interpreting complex blueprints, and executing intricate processes. Continuous training and professional development ensure that personnel have the knowledge and expertise to deliver accurate results consistently.

7. Achieving Tight Tolerances

Tight tolerances are a hallmark of precision manufacturing. It refers to the permissible deviation from the desired measurements or specifications. Manufacturers strive to achieve tight tolerances to ensure that products meet precise requirements and perform optimally. This level of accuracy is often demanded in industries such as aerospace, medical devices, and automotive.

8. Benefits of Precision Manufacturing

Precision manufacturing brings numerous benefits to both manufacturers and end-users. High-quality products with exceptional accuracy result in improved performance, enhanced reliability, and extended product lifespan. Precision manufacturing also reduces waste, minimizes errors, and increases overall efficiency, leading to cost savings and customer satisfaction.

Conclusion

Precision manufacturing is a critical aspect of modern industry, emphasizing accuracy and attention to detail.

By leveraging advanced technologies, implementing quality control measures, optimizing designs for manufacturability, and investing in a skilled workforce, manufacturers can achieve exceptional accuracy in every step of the production process.

The realm of precision manufacturing offers insights into the value of accuracy in creating high-quality products that meet the demands of today’s industries.

Muhammad Asif Saeed, a seasoned professional in commerce and finance, holds a Bachelor of Commerce degree specializing in Accounts and Finance, complemented by an MBA with a focus on Marketing. With an impressive 20-year career in Pakistan’s textile sector, including roles at Masood Textile (MTM) and Sadaqat Limited, he excels in business and financial management.

Muhammad Asif Saeed is also a recognized authority in the field, contributing authoritative articles to renowned websites such as businessproplanner.com, businessprotips.com, distinctionbetween.com, trueqube.com, and bruitly.com. His insightful perspectives on complex finance and business operation topics underscore his comprehensive knowledge and professional expertise.